Did you know that the pipe and tube bending machine market is projected to reach $6.02 billion by 2031? This shows the growing demand for high-quality pipe-bending services across various industries.

In engineering and fabrication, pipe bending quality is crucial. It affects the strength and durability of structures and machines. Proper bending keeps pipes strong and functional under pressure.

Different industries, like automotive, construction, and manufacturing, need precise bending. Each industry has unique requirements. This article highlights the top custom pipe-bending services that provide durable results.

Conventional Pipe Bending

Conventional pipe bending is widely used in many industries. It uses standard equipment to bend pipes to the required angle and radius. This method is great for projects needing function and a clean look.

This method works well for plumbing, construction, and automotive needs. It ensures that pipes fit into different systems. Many companies choose it for its reliability and cost-effectiveness.

Mandrel Bending

Mandrel bending is ideal for tight bends without losing pipe strength. A mandrel tool supports the pipe during bending. This prevents collapse and keeps the pipe’s shape.

It is commonly used in the automotive industry. This method improves durability and strength. It works well for high-pressure applications.

Mandrel bending also helps reduce stress on pipes. This can make them last longer. Many industries use this method for reliable and precise bending.

Heat Induction Bending

Heat induction bending uses heat to bend pipes smoothly. It warms specific sections before bending. This allows for precise curves and intricate shapes.

It is ideal for large-diameter pipes. Many industries use this method for strong and accurate bends. It helps prevent material fatigue.

This technique is common in industrial applications. It creates complex shapes that other methods cannot. It also ensures durability and strength.

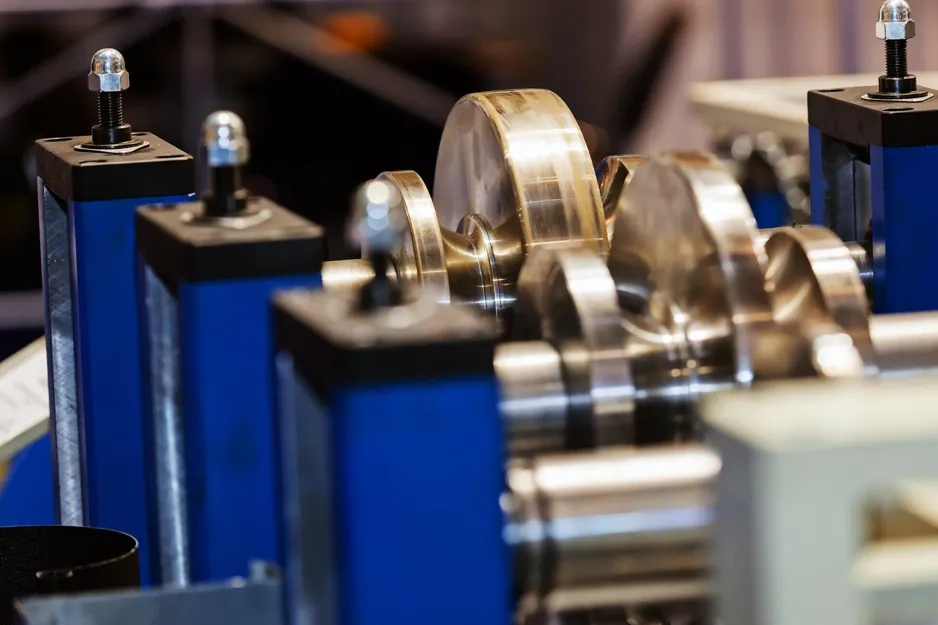

Rotary Draw Bending

Rotary draw bending is a highly precise method. It uses a rotating die to bend the pipe. This ensures accurate and consistent results.

It is popular in the aerospace and automotive industries. These industries need exact specifications. The process helps reduce material waste.

Less waste means lower costs for projects. It is also better for the environment. Many manufacturers choose this method for its efficiency.

Electro-Hydraulic Bending

Electro-hydraulic bending uses hydraulic and electronic controls. This ensures precise and accurate bends. It is ideal for large-scale production.

The technology improves consistency and repeatability. It works with different pipe materials and sizes. This makes it a flexible option for many projects.

High-speed operations increase efficiency. Many industries choose this method for its reliability. It helps speed up production while maintaining quality.

Tube Bending Services

Tube bending services focus on thin-walled tubes. They provide precise solutions for complex designs. This method ensures tight tolerances and accurate bends.

It is widely used in the automotive and machinery industries. These industries need both performance and aesthetics. Tube bending improves both function and appearance.

This method helps create smooth and sleek designs. It ensures that tubes fit perfectly in different systems. It enhances both durability and visual appeal.

Investing in Quality Pipe Bending Services

The right pipe bending service affects durability and performance. Different methods offer unique benefits. Each technique suits specific applications.

Using the right service improves strength and function. Industries rely on these methods for better products. Quality bending ensures long-lasting results.

If you’d like to learn more, check out more articles on our blog.